New Construction Hydronic Installation

Hydronic design for new builds, engineered for altitude

Hydronic design for new builds starts with precision. We perform detailed load calculations, zoning layouts, and equipment selection matched to your region’s altitude and your home’s design.

Advanced Hydronics

coordinates directly with architects and builders so tubing patterns, manifolds, and mechanical-room layouts integrate cleanly with construction schedules and finished spaces.

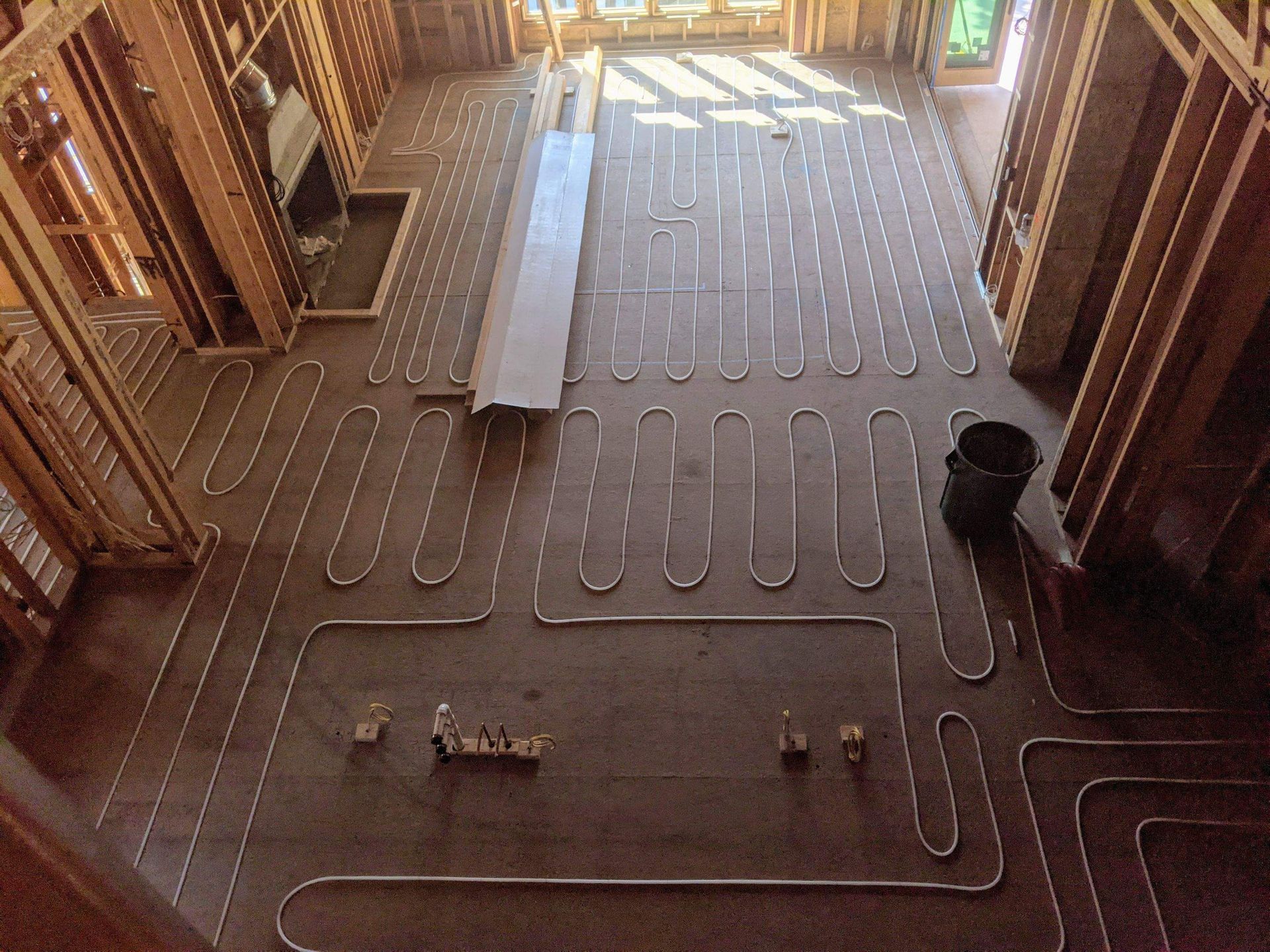

Radiant floor heating for whole-home comfort

Radiant floor heating sets the standard for quiet, even comfort. It works beautifully as primary heat in new homes, whether poured in slab, overpour, or under-joist assemblies. Open layouts in areas like Wash Park, Sloan’s Lake, and Cherry Hills Village stay draft-free, with warmth that feels natural and finishes that remain the visual focus.

- Even, draft-free heat through slab, overpour, or under-joist assemblies.

- Custom zoning by room or level for balanced comfort in any home size.

- Compatible with hardwood, tile, and stone; ideal for open plans and basements.

- Lower water temperatures improve efficiency at Denver’s altitude.

- Silent operation and cleaner indoor air without moving dust.

High-efficiency boilers, smart zoning, and abundant hot water

Each system begins with a right-sized modulating condensing boiler, tuned for Mile High performance and long-term efficiency. Outdoor reset and smart zoning keep temperatures steady while reducing fuel use. For domestic hot water, an indirect water heater pairs with the boiler to deliver fast recovery and consistent capacity without electric elements or standby loss.

- Right-sized, modulating condensing boiler tuned for elevation efficiency.

- Outdoor reset and smart zoning for steady temperatures and reduced fuel use.

- Organized mechanical rooms with labeled manifolds and ECM circulators.

- Indirect water heater for fast-recovery hot water with minimal standby loss.

- Simple, modern controls with app-enabled options.

Discover why hydronics makes a difference

Quiet, even warmth, cleaner air, and energy efficiency set hydronic systems apart from forced air.

What to expect during you new-build

Expect coordinated drawings, rough-in checklists, site protection in occupied phases, and commissioning documents at turnover. Your project lead keeps decisions moving and milestones on track, fewer surprises, cleaner mechanical rooms, and a handoff your GC will appreciate.

Plan the right system from the start

Every new build is different. Learn how boilers, heat pumps, and heat emitters work together to create comfort that lasts.

What to Know When Building with Hydronics

When should hydronic design begin in a new build?

As early as possible. Starting design during the architectural or mechanical planning stage allows tubing routes, manifolds, and mechanical-room layouts to integrate smoothly with framing and other trades. Early coordination also prevents conflicts with floor assemblies, electrical, and plumbing runs.

How does hydronic installation fit into the construction schedule?

Hydronic rough-in typically aligns with framing and other mechanical work. Tubing, manifolds, and boiler piping are installed before drywall and finishes, while final commissioning and controls setup occur near project completion.

What information do you need to start design?

Scaled floor plans, window and insulation details, and floor assembly information let us calculate loads accurately and select the best assemblies and equipment for each zone. We also coordinate closely with your builder to confirm elevations and finish materials.

How do you coordinate with architects and builders?

We provide clear drawings and specifications early in the process, then stay in communication through framing and rough-in. Our team ensures manifolds, control wiring, and mechanical-room layouts meet design intent and fit within the construction schedule.

Can hydronic systems handle multiple loads like heat and domestic hot water?

Yes. A single high-efficiency boiler or heat pump can serve space heating, snow melt, and domestic hot water. These multi-load designs reduce redundant equipment and simplify the mechanical room while maintaining performance and reliability.

What should homeowners expect during installation?

Our team works in sequence with other trades to ensure a clean, organized installation. After pressure testing and final commissioning, we document controls, zone layouts, and maintenance information so the system remains easy to operate and service for years to come.